The Engineering Difference, The Power Behind The Press

PressSure™ Technology

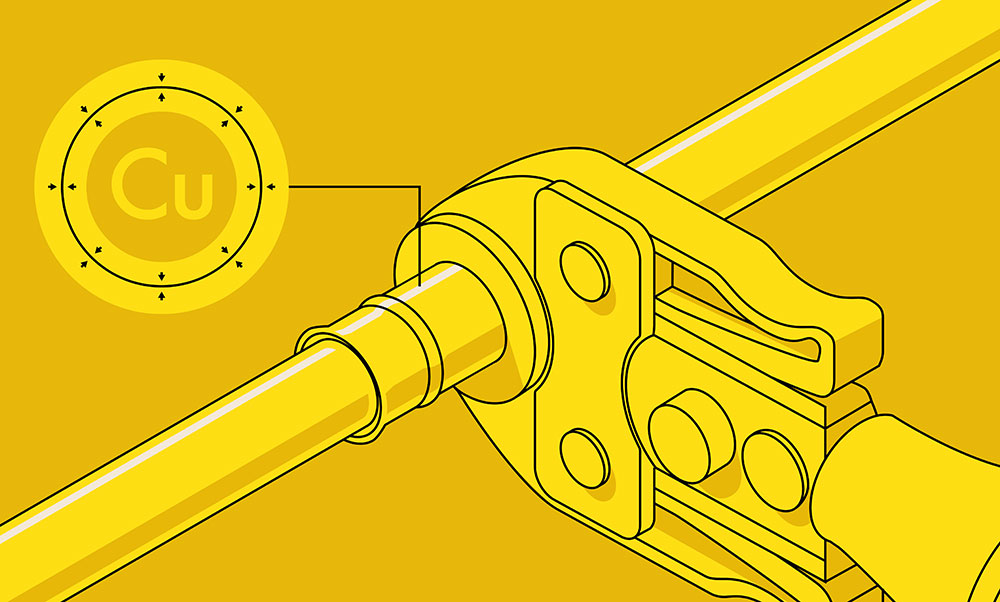

At the heart of every RLS press fitting is PressSure™ Technology, our patented innovation that delivers unmatched reliability and strength for HVAC and refrigeration systems. When performance matters, PressSure™ delivers peace of mind with every press.

This innovative system utilizes annealed copper with dual mechanical and static seals for a 360° leak-proof connection. The unique work-hardening process strengthens the copper during pressing, providing enhanced durability and resistance to pressure fluctuations and vibration over time. With a wide range of jaw and fittings sizes, the system offers unmatched flexibility, making it the ideal solution for HVAC/R professionals to press forward with confidence.